Comfort Control has recently had the privilege of working on several commercial kitchen projects as a design-build and spec-build contractor. Each project has provided its own unique challenges for providing adequate temperature control, exhaust and ventilation.

The exhaust hood is one of the most critical components to a commercial kitchen functioning as it was designed. The type, size and quantity of equipment being placed under the hood makes a significant impact on the exhaust equipment, ductwork and insulation required by code.

Double wrapped, zero clearance grease duct in an attic adds significant costs associated with the labor to install a commercial kitchen exhaust system.

Type I exhaust hood – A type one exhaust hood is required when grease laden fumes are created by the food/equipment which they serve. Ductwork serving a Type I hood is required to be welded (or a pre-fabricated, UL listed weld free grease duct system), include cleanouts at each change of direction, pitch back towards the exhaust hood and be double wrapped in an approved fire blanket for zero clearance to combustible. Type I hoods require Ansul fire suppression in the event of a grease fire anywhere in the exhaust system. Typical equipment requiring a type I hood are fryers, broilers, grilles and griddles.

Type II exhaust hood – Type II hoods are used for heat only applications and can be exhausted using 22 ga., snap joint ducowork. Typical equipment requiring only a type II hood are toasters, and some pizza ovens.

In addition to the different exhaust requirements, ventilation in a commercial kitchen is handled differently than normal commercial spaces. Typically, a dedicated make-up air unit is ducted to a make-up plenum integral to the exhaust hood. In addition to the dedicated make-up air volume, the comfort HVAC system is responsible for providing up to 20% of the total hood capacity. Additionaly, careful consideration must be given to the airflow patterns in the immediate vicinity of the exhaust hood and proximity of the make-up air intake to the exhaust fan discharge. Perforated diffusers are preferred to 4-way cone diffusers so as not to disturb the airflow pattern entering the hood and any fresh air intakes must be a minimum of 10′ from the discharge air stream of an exhaust fan.

A minimum of 10′ must be maintained between all fresh air intakes and exhaust discharge air streams.

Welding approved exhaust duct and fittings in an attic can be difficult, dangerous and often extremely costly. For this reason, many hood manufacturers now produce pre-fabricated “weld-free” exhaust duct. Using a special adhesive and v-clamp on each joint, this design satisfies the UL requirements for high temperature grease duct. Available in single and double wall construction, this product is more expensive than welded ductwork and requires the layout be finalized prior to ordering material, but the reduction in labor hours necessary for installation make it a cost effective alternative.

Another consideration when designing the HVAC system for public spaces such as a bar or restaurant is the minimum outdoor air requirements of ASHRAE 62.1. This regulation requires that 7.5 cfm per occupant and 0.18 cfm per square foot of outside air be provided to the space at all times. If the maximum capacity of a 5,500 ft² restaurant is 100 people, the HVAC system should be capable of providing 1740 cfm of ventilation. At the extreme temperatures experienced in the summer and winter months it can be very costly to heat and cool such a large volume of 100% outside air. To help reduce unnecessary energy consumption, demand control ventilation is often used to provide only the minimum amount of OA necessary. Occupancy sensors, CO2 sensors, timers or all three provide the HVAC system with feedback on the existing conditions to m modulate the quantity of outside air being provided to the space. based only on the occupants currently present.

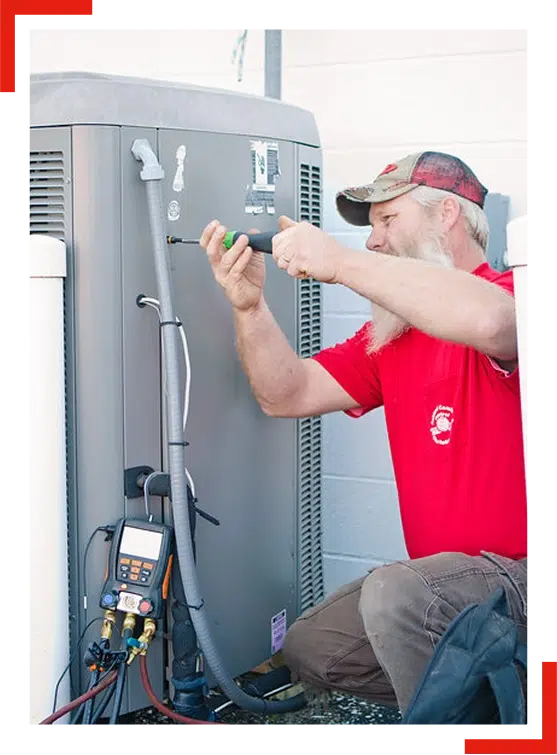

Correctly setting the defrost schedule/timer on a kitchen cooler is important to maintain stored food temperatures without freezing up the unit.

Walk in coolers can present challenges of their own for someone that may not be familiar working with refrigeration devices and some of the nuances of this equipment. In addition to different refrigerants than normal HVAC equipment, careful consideration must be given to setting the defrost timer and evaporator setpoint on the unit to prevent the unit from freezing up and maintaining proper food temperatures. The evaporator setpoint should often be established based on the temperature the unit is maintaining, and not the integral dial on the unit as this is often inaccurate.

A final item that often needs addressed is the growing desire for open patios, outdoor seating, large operable windows and roll up garage doors in restaurants. High intensity gas patio heaters can help extend the outdoor eating season for several weeks in the fall while overhead air curtains help deter insects and contain conditioned air inside in the summer. Each of these types of equipment can be specified in individual lengths up to 10 feet and are available in finished suitable for exposure to outdoor weather conditions.

These examples are only a few of the many items that need to be taken into consideration when designing a commercial restaurant HVAC system. Comfort Control has experience working with a variety of general contractors and manufacturers on both local and national restaurant brands and is always interested in lending our expertise to any restaurant, bar or kitchen project.